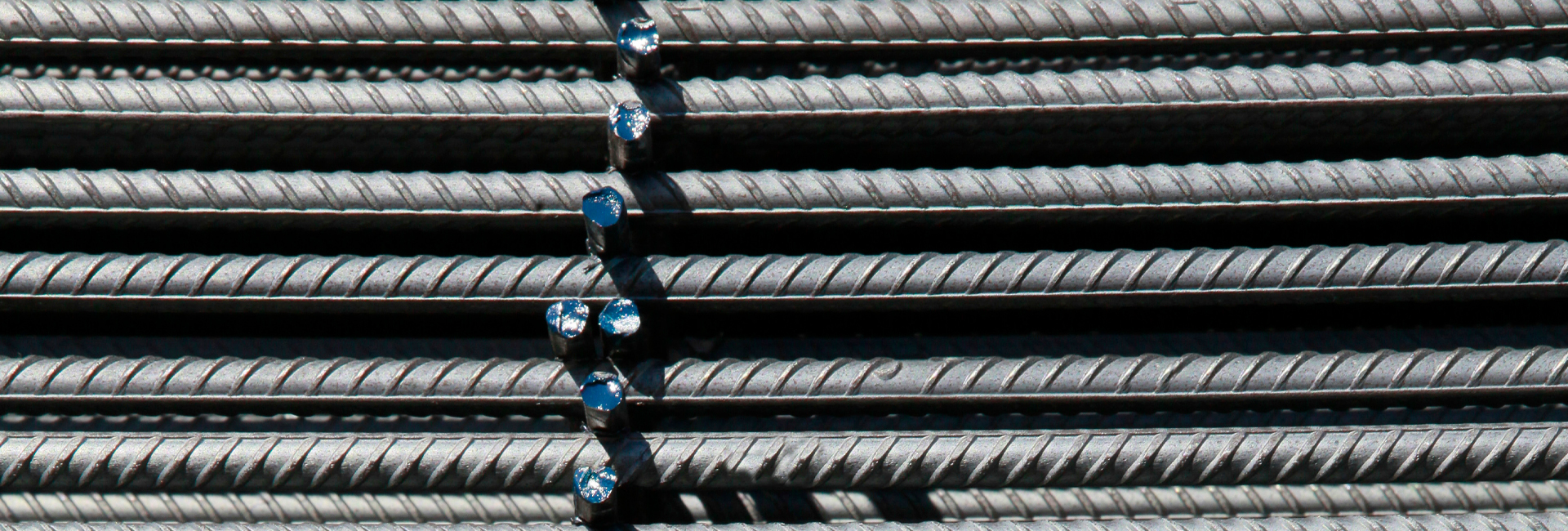

What Are TMT Bars?

Thermo-Mechanically Treated bars or TMT bars are carefully curated and produced by TMT manufacturers to ensure optimum tensile strength and durability. TMT bars that are available in India are usually graded depending on their content. In manufacturing plants, TMT bars are graded as 550D, Fe500, Fe550 and Fe600. Read More: https://sreemetaliks.com/blog/what-are-the-different-grades-of-tmt-bars As the superior qualities of TMT bars are not naturally found in Iron ores, TMT bars are artificially manufactured in industrial plants through processes like quenching, thermo-mechanical treatments, self-tempering, and atmospheric cooling.

|

Table of Content

|

Factors Affecting The TMT Bars Level Of Quality

TMT bars are highly sought after in the construction industry, because of their high endurance capacity and strength. Today, we have numerous TMT bar brands claiming to have the best quality and offer longevity. It can be overwhelming to pick from multiple options but one needs to make an informed decision. It is a no-brainer that the choice of materials for construction is highly dependent on the geography, climate, and quality of the land. But what kind of ore fits the quality standards of TMT bars perfectly? What determines the quality of a steel bar? The selection of TMT bars ultimately decides the sustainability of the construction. And no one would want to risk investing in bars that do not offer value for the money. The best TMT bars can be spotted just by considering a few factors. The following factors are the most important criteria that determine what makes it to the construction area and what does not.

Composition Of Chemicals

Chemical composition is the fundamental aspect of any TMT bars. All the strength and durability a bar offers to the building is an outcome of the materials present in it. The presence of top-quality iron ore should be ensured to avoid the involvement of poor-quality products. Similarly, the carbon content in the bars must be low to ensure perfect weldability. It is also important to make sure that the right balance of carbon, sulphur, and phosphorus is found in the bars. Any unnecessary substances like non-metallics and cast iron should be avoided by any chance.

Manufacturing Procedure

The standard of TMT bars is ultimately dependent on the way they are manufactured. A series of processes take place when a high-quality TMT bar manufacturing is in the making. The controlled manufacturing process involves quenching, rolling, and atmospheric cooling which gives the bars the strength they need. The more the impurities leave the bars through the heat treatment, the stronger and more ductile the bars remain. This will help the bars withstand natural calamities and protect the buildings.

Dual Ribbed TMT Steel Bars

The rib structure of a TMT bar tells a lot about the durability of the concrete. This is why modern construction specialists prefer dual Ribbed TMT steel bars. They are responsible for bolstering the concrete structure while also allowing the tensile strength to be intact for a more extended period of time. Another interesting fact about dual Ribbed bars is that they offer much-needed weather resistance and better grip on the concrete.

The Reputation Of a Brand

Brand reputation is a result of the unwavering quality that a business offers its product. Consequently, consumers build their trust around the products and the brand. Construction specialists prefer TMT bars from reputed brands because they do not compromise on the quality of the construction. It is important to make sure the bars are certified for protection against corrosion, natural calamities, and fire. Thorough research on TMT brands that offer international certifications such as BIS or ISO can go a long way in the business.

Our modern world is heavily reliant on TMT bars for the construction of buildings, statues and other urban structures like bridges, flyovers and stadiums. TMT bars are most favored for constructions as they are unparalleled in terms of their tensile strength and durability. In addition, TMT bars are industrially manufactured for offering a higher strength reinforcement. They are typically known for their stronger outer core and tender inner core, ensuring greater flexibility and ductility. Due to their enhanced strength, TMT bars are popularly used for protection against floods, earthquakes, and other natural calamities.

Why Use Premium Quality TMT Bars For Construction?

Superior grade TMT bars are commonly used for urban as well as suburban constructions. This is because of the unique benefits of TMT bars mentioned below:

-

Flexible:

TMT bars are extremely flexible, which is not just helpful during construction, but also allows them higher resistances against physical damages. Earthquake resistance TMT bars are widely used for regions prone to earthquakes and floods. -

Elongation & Ductility:

They are popularly known for their superior elongation, ductility, and better working abilities. -

Resistance:

TMT bars offer greater resistance to corrosion and chemical reactions like oxidation and rust, making your construction durable. -

Cost Effective:

They are cost-effective. Being lightweight, they can be conveniently transported at lower costs and require very little maintenance. -

Eco-Friendly:

TMT bars are eco-friendly since they can be recycled with their properties uncompromised.

Characteristics Of High-Grade TMT Bars

TMT bars that are best suited for urban construction have the following properties:

- Have a carefully proportioned blend of carbon and manganese for greater bonding capacities. The carbon-manganese content in TMT bars suited for construction is 0.42%.

- Have a heat resistance of 600°C to 650°C.

- Are characterized by their uniform rib patterns with wide elongated ends.

Sree Metaliks Limited’s (SML) TMT Bars – The Titan of TMT Bars in India

Looking for the best TMT bar for your construction project? The place to find the best premium TMT bars in India is SML. They offer a wide range of high-quality TMT bars that are ideal for construction. Since 1995, SML has been recognized as a pioneering company that produces the best TMT bar in India. The TMT bars manufactured and distributed by Sree Metaiks Limited have a superior grade and are thermo-mechanically treated for higher durability and tensile strength. The Thermax manufacturing process allows the TMT bars to withstand physical damage, corrosion, and chemical reactions for a longer time. Other than the best TMT bars at affordable rates, SML also offers high-end iron ore, pig iron, iron billets, and iron ore pellets for construction and more. . Read More: The Guide To Buying The Best TMT Bars Why choose TMT bars of integrated plants instead of small rolling mills? Which TMT Bar to buy for building your house? 5 Tips to Make an Earthquake Resistant Building

For more information, please reach out to us at: Sales@sreemetaliks.com