Steel has played a major role in the development of modern architecture and has become an essential material for the construction of tall buildings, bridges, and large structures. The material’s strength, durability, and versatility make it ideal for use in a variety of building designs.

|

Table of Content

|

“In 2020, 1,864 million metric tons of crude steel were produced globally, making it the foundation of our buildings, vehicles, and industries. Steel production has tripled in the past 50 years, despite some nations reducing their domestic production. Steel’s strength lies in its infinite recyclability with no loss of quality, making it 1,000 times stronger.”

Various Role of Steel in Modern Architecture

Steel plays a pivotal role in modern architecture due to its versatility and strength. Its malleability allows for innovative designs, including curved structures and intricate detailing. Modern steel architecture’s durability and resistance to environmental factors make it ideal for long-lasting constructions. Steel is also employed in building facades, roofing, and interior elements. Sustainable steel production contributes to eco-friendly building practices, emphasizing its multifaceted role in shaping contemporary architectural achievements.

Exceptional Properties of Steel in Architecture

One of the main advantages of using steel in architecture is its ability to span great distances without the need for intermediate supports, which results in open, flexible spaces for the building’s occupants. Steel also has a high resistance to fire and pests, which makes it ideal for use in high-rise buildings and other structures where safety and durability are of utmost importance.

The Versatility of Steel in Architecture

In addition, steel’s ability to be fabricated into complex shapes and designs means that architects and engineers have a wide range of options when it comes to designing their structures. This allows them to create unique and innovative designs that might not be possible with other building materials.

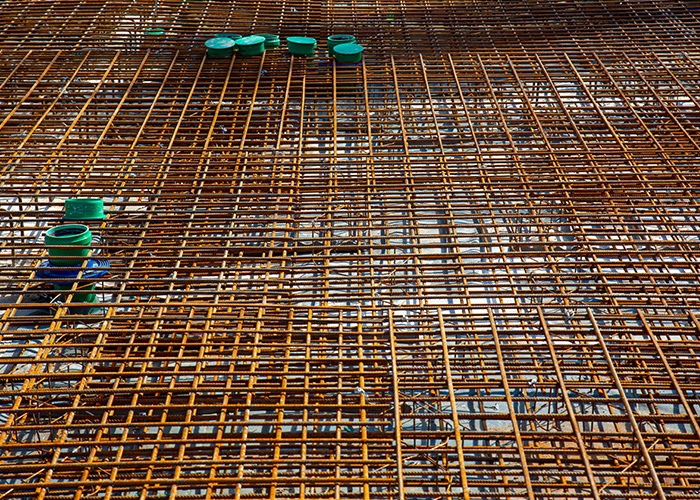

Using Steel in Architecture to Accelerate Construction

The use of steel in architecture has also led to a decrease in construction time, as well as increased efficiency in construction processes. Steel components can be prefabricated in a factory and then transported to the construction site for assembly, which reduces the amount of time required for on-site construction.

Maximizing Floors with Efficient Steel Construction

The use of steel in construction enables buildings to have more floors within a given height. Steel beams don’t need to be as deep as concrete beams to support the floor, resulting in more efficient structural construction.

Lighter Steel Section Increases Efficiency and Floor Space

Steel’s ability to support lighter sections enables it to maintain the same load-bearing capacity per floor, providing up to 1.5 times more floor space within the same exterior height. Additionally, the smaller column size compared to concrete results in an increased carpet area.

Maintenance and Expense of Steel Architecture

Despite its many advantages, the use of steel in architecture is not without its challenges. The material is subject to corrosion and requires a significant amount of maintenance to ensure its longevity. Additionally, the fabrication and transportation of steel components can be costly, which can make steel-framed structures more expensive to construct than those made from other materials.

Conclusion

Overall, steel has become an essential material for modern architecture due to its strength, versatility, and ability to support the construction of large and complex structures. Whether used for its ability to span great distances or its ability to be fabricated into unique designs, steel has proven itself to be a critical component of modern building design.

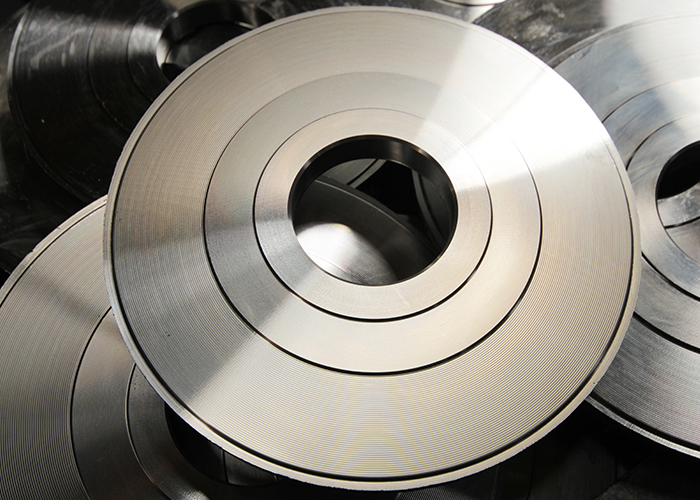

Sree Metaliks Brings You the Best Type of TMT Bars

Sree Metaliks Limited, established in 1995, has built a solid reputation in the construction sector. Their raw materials span a wide range, including Iron Ore, Sponge Iron, Billets, Pig Iron, Pellets, and TMT bars. High-quality TMT bars made by Sree Metaliks Limited are employed in several construction projects.

Sree Metaliks Limited produces different types of TMT bars that adhere to high international standards. Therefore, Thermax Quenching System & Technology of Hennigsdorfer Stahl Engineering, GMBG, Germany, has granted them a license. This license serves as a gauge for power and adaptability.

With the help of specialists, Sree Metaliks Limited creates the best type of TMT bars for building. The TMT bars are manufactured at its cutting-edge facility in Loidapada, Odisha. Additionally, Sree Metaliks TMT bars are fully compliant with the BIS standard.

For more information, please reach out to us at: Sales@sreemetaliks.com